Cold Drawn Cold Rolled Precision Steel Pipe

Precise custom outer diameter and inner diameter

Tight tolerances, resulting in reduced machine time / Dimensional accuracy

Smooth and Clean OD and ID surfaces

Excellent machining characteristics

Wider range of physical properties attainable through process and annealing options

Product Description

Seamless Steel Tube

Precise custom outer diameter and inner diameter

Tight tolerances, resulting in reduced machine time / Dimensional accuracy

Smooth and Clean OD and ID surfaces

Excellent machining characteristics

Wider range of physical properties attainable through process and annealing options

Product Description /Specifications

Production Range | Outer Diameter:10-120mm (0.4 inch - 4.7 inch) |

Wall Thickness:1-20mm (0.04 inch - 0.78 inch) | |

Material / Grade | Carbon Steel: GB/T 8162 & 8163 & 3639: 10#, 20#, 35#, 45#, 55#, Q235B, Q235C, CF53, A105 ASTM A519: 1010, 1020, 1026, 1035, 1045, 1050 DIN17121/EN 10297-1, DIN1629/DIN2391/EN 10305-1: C10/CK10, C22/CK22, C35/CK35, C45/CK45, CF53 JIS3441/JIS3444/JIS3445: STKM11A, STKM12A/STKM12B/STKM12C, STKM13A/STKM13B/STKM13C JIS G4051: S10C, S20C, S25C, S35C, S45C, S55C |

Alloy Steel: GB/T 8162 & 8163 & 3639: 16Mn(Q345B), 20Cr, 40Cr, 15CrMo, 20CrMo, 28CrMo, 30CrMo, 35CrMo, 42CrMo, 20CrMnTi, 40MnMoV, 20Mn2, ZF6, 16MnCr5, 20MnCr5, 38Mn2V, 09CrCuSb(ND) ASTM A519: 5120, 5140, 4130, 4135, 4140 DIN17121/EN 10297-1, DIN1629/DIN2391/EN 10305-1: ST52, EN10084-1998 20Cr4, 41Cr4, 15CrMo4, 25CrMo4, 35CrMo4, 42CrMo4, 16MnCr5 JIS3441/JIS3444/JIS3445: SCM432/SCRRM3, SCM4 JIS G4053: JIS SCr420, JIS SCr440, SCM415, SCM420 | |

Tolerance | Tolerance ±0.15mm,Superior products ±0.05mm, Can be customized according to customer's requirements |

Technique | Cold Drawn / Cold Rolled |

Shape | Round |

Further Processing for Steel Tubes | Final Annealing, Cutting, Chamfer, Threading, Inner diameter or Outer Diameter Lathe, Surface Shot Blasting, Laser Marking |

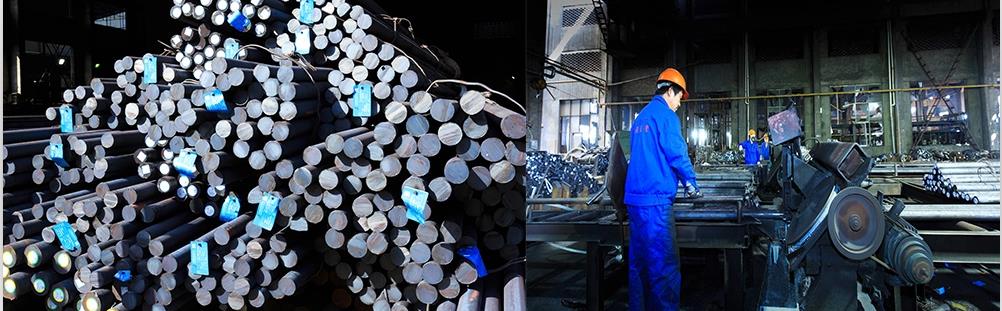

Production process of seamless steel pipe

Row Material storage/inspection and cutting by saw machine

Hot Perforaction

Squeeze head and raw tube inspection

Cycling pickling

Cycling cold drawing/roling

Cycling annealing

Straightening

Eddy current inspection

Products inspection and test

We have our own workshop, we can supply one stop service:

1. Blasting machine.

2. Fiber machine cutting machine.

3. Bending machine.

4. Drill holes machine.

5. Fully automatic paint room.

6. Welded machine.

We passed certificate ISO9001, ISO14000, OHSAS18001. As a member of China iron and steel association, we established long term friendly cooperation with famous domestic mill plants,such as Bao steel, Wu steel, An steel, Tai steel etc. As well as active pursues partnerships foreign company, in order to meet customer requirement. With concept of "Keep Improving, Win-win Cooperation', and executed by reliable quality and after sales service system, Qigang gained good reputation from customers at home and abroad. We sincerely welcome you to come our company to negotiate business.