Mn13 High Manganese Hadfield Wear Resistant Steel Plate

Mn13 is a high-manganese wear-resistant steel with work hardening characteristics that other wear-resistant materials cannot match. Under the action of greater impact load or greater contact stress, the surface of the steel plate will be work hardened, and the surface hardness will rapidly increase from HB200 to HB500 Above, a highly wear-resistant surface layer is produced, and the austenite in the inner layer of the steel plate still maintains good impact toughness.

Mn13 is a high-manganese wear-resistant steel, which is the best choice among wear-resistant materials such as strong impact and high pressure material wear. There are two biggest characteristics of high manganese steel:

1. The greater the external impact, the higher the wear resistance of its own surface layer;

2. the second is that as the surface hardened layer gradually wears, new work hardened layers will continue to form. The Mn13 rolled steel plate has excellent wear resistance against strong impact wear and high stress wear, will not be broken during use, and has easy machining properties such as easy cutting, welding, and bending. The traditionally used high chromium cast iron only has better wear resistance against mobile wear. Mn13 rolled steel plate can effectively reduce the use cost of equipment wearing parts, save equipment maintenance costs, and improve the competitiveness of finished products.

Mn13 Chemical Composition | ||||

C | Si | Mn | P | S |

0.90-1.20 | 0.30-0.80 | 11.00-14.00 | ≤0.035 | ≤0.030 |

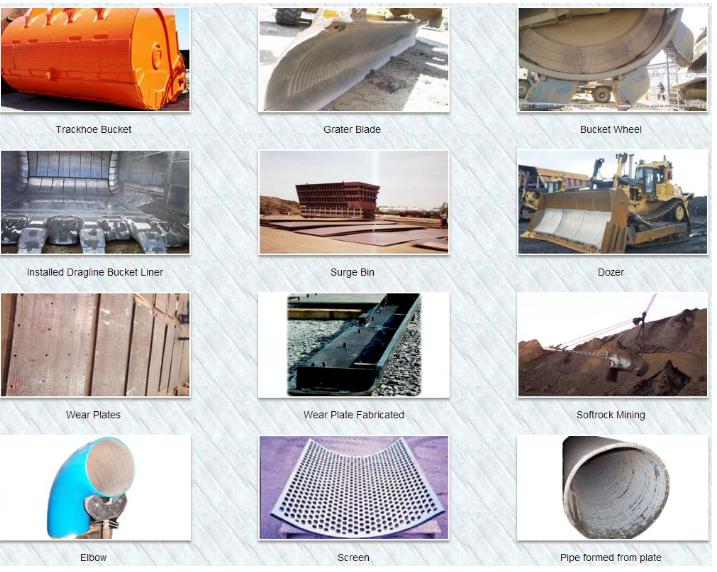

Applications

The special performance of high manganese steel is suitable for making wear-resistant components that can withstand high impact materials for a long time. It has been widely used in metallurgy, mining, building materials, railways, electric power, coal, and other mechanical equipment for a long time. Especially in recent decades, with the rapid development of modern industry and the rapid advancement of science and technology, high manganese steel has become the preferred wear-resistant material in advanced equipment such as maglev trains, safes, bulletproof vehicles, rock drilling robots, and new tanks. Many new materials and modern surface engineering technologies are still unable to compare with high manganese steel in terms of cost performance.

Mechanical behavior | |||||

tensile strength | Elongation | Impact performance 20ºC | Initial hardness value (HB) | Hardness value after hardening (HB) | Cold bend 180° |

≥800MPa | ≥40% | ak≥90(J) | 200-250 | >300 | qualified |

Advantages

1. For cutting Mn13 high manganese wear-resistant steel plate, plasma cutting is recommended.

Plasma cutting is divided into underwater plasma and air plasma cutting. When using underwater plasma cutting, the plasma gas can produce thousands of degrees of high temperature, the high manganese steel plate is melted quickly at the cut, and the water is blocked to avoid oxidation, and the water cools the steel plate in time to prevent the precipitation of carbides and cut the steel plate. The surface is smooth and flat, there is no heat-affected zone, and the cutting quality is the best. It is the first choice for cutting high manganese steel. Air plasma cutting can also be used.

2. Mn13 high manganese wear-resistant steel plate can also be cut by traditional flame.

When using flame cutting, it is recommended to use a cutting trolley. According to the thickness of the steel plate, use different specifications of the gun head, and adjust the ratio of gas and oxygen appropriately (preferably a neutral flame), and it is best to start cutting after all adjustments. Prevent the cross-section gap caused by the midway flameout and arc ignition, which affects the cutting quality.

3.Welding of Mn13 high manganese wear-resistant steel plate

Manual arc welding can be used for welding high manganese wear-resistant steel plates. Before welding, the welding seam should be polished, and the groove and edge of the workpiece should be thoroughly cleaned to remove rust and oil stains. At the same time, the electrode should be dried; when welding, a small diameter electrode (usually 3mm-3.5mm), small current, high voltage, Multi-layer welding, multi-pass, fast welding; if DC welding is used, the electrode is connected to the positive electrode; after each layer is welded, the weld must be hammered to improve its thermal crack resistance. You can also use running water to cool down quickly.

Company introduction

Shandong Ruinai Steel Sales Co., Ltd is located in Liaocheng City, west of Shandong province, it's about 400 Km in the south of Beijing city, and 100 Km in the west of Jinan city, and benefit from the convenient traffic condition, Liaocheng economy develops rapidly and formed the largest steel logistics center in the north of China. Ruinai Steel is a subsidiary of Lai Steel Group, founded in 2018 and engaged in the production and sales of wear resistant steel plates, weathering steel plates, high strength carbon steel plates, stainless steel, aluminum, brass, and sectional materials. Except for the stock product, we also have our own factory and workshop, stainless steel welded pipe factory, that has 24 lines to produce the welded pipe(round and rectangle pipe), out diameter and width: 5mm-610mm, thickness: 0.5mm-20mm.

We have our own workshop, we can supply one-stop service:

1. Blasting machine.

2. Fiber machine cutting machine.

3. Bending machine.

4. Drill holes machine.

5. Fully automatic paint room.

6. Welded machine.

We passed certificates ISO9001, ISO14000, and OHSAS18001. As a member of China's iron and Steel Association, we established long-term friendly cooperation with famous domestic mill plants, such as Bao Steel, Wu Steel, An Steel, Tai Steel, etc. As well as actively pursues partnerships with foreign companies, in order to meet customer requirements. With the concept of "Keep Improving, Win-win Cooperation', and executed by reliable quality and after-sales service system, Ruinai Steel gained a good reputation from customers at home and abroad. We sincerely welcome you to come to our company to negotiate business.

Cooperative company

Ruinai Steel is a subsidiary of Laiwu Steel Mill Plant , with business continues expanding and customer different requesting of variety steel product , we established long term friendly cooperation with famous domestic mill plants , such as Baosteel Group / Wusteel Group / Ansteel Gropu / Taisteel Group etc . In order to assure quality and delivery time , we keep mass stock of regular size steel materials all the year round , we welcome clients come to our warehouse have an inspection .

As a international company we also pursues partnerships with SSAB and POSCO positively .

Processing customized

Ruinai Steel can do many service.

We have our own Sandblasting spray paint line , can paint different colors for different products .

We have several cutting machine ( flame cutting machine , laser cutting machine , plasma cutting machine , sawing machine ) can cut plate thickness up to 100mm, and different sharp as Customer inquiry .

We can also drilling holes on plate , and pipes . We can also do descaling , chip removing , welding Fixed length , bending , galvanize ,3PE coating etc . Whatever you have demand , tell us , we wil try our best to satisfy you .

Exporting countries

Since the establishment in 2012, Ruinai has always aimed at products ’ quality and customers benefit keep working on improving the performance of steel and customer service . So far , our products have been sold far to Malaysia , Vietnam , Singapore , USA , Greece , Russia , Mexico Australia , Canada , Chile , Peru , Colombia , South Africa , Guyana , etc , and other countries and regions , and a famous brand name with international recognition and reputation . Our company has a team of international sales staffs who are familiar with the steel who know wel about the procedures of the export business and certificate . We have many warehouses , and the import and export license providing a dragon and professional trade service of brand steel products from purchasing , quality inspection , storage and LCL ( Less than container load ) to export.

Our advantage

DELIVER

More than 2000 tons stock at hand, delivery time is short, usually 3-7 days.

QUALITY INSPECTION

3 times quality test before delivery to make sure the good quality.

PACKAGE

Professional packing,we can also do as per customer's requirement.

OEM

Provide size customized service.

SERVICE

Provide Bending, Punching,Welding, Cutting, Decoiling,Surface treatment service.

SAMPLE

Provide the free sample for your inspection and check.

INDIVIDUALITY

Personalized customization service: add company logo on product; specify color, etc.